Sensors

Showing all 5 results

FD-QT

Laser Tracking Sensor

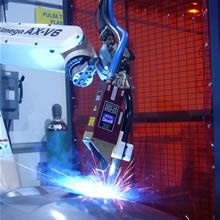

The FD-QT system features a high-end laser sensor with real-time seam tracking. Used for compensating for gaps, part distortion, inconsistencies, tacks and other small defects with extreme accuracy and rapid feedback. The FD-QT system has a lot of flexibility and can be used in a wide variety of applications. FD-QT can automatically detect the tracking, start, and end points of welding. Additionally, since the FD-QT sensor processes data in realtime, no additional time is required for checking parts, leaving cycle times unaffected. [btn text="Download more information" tcolor=#FFF bcolor=#004098 thovercolor=#FFF link="https://daihen.mx/wp-content/uploads/2020/04/Sensing-Solutions.pdf" target="_blank"]

FD-TR

Need the highest degree of precision during robotic TIG arc welding? Upgrade your setup with DAIHEN’s FD-TR system, the leading edge real-time robotic tracking sensor used to maintain optimal welding conditions.

By measuring arc voltage during welding, the FD-TR arc sensor moves the torch vertically in order to maintain the best possible constant arc length. Feedback is relayed via the tungsten electrode in the torch.

[btn text="Download more information" tcolor=#FFF bcolor=#004098 thovercolor=#FFF link="https://daihen.mx/wp-content/uploads/2020/04/Sensing-Solutions.pdf" target="_blank"]

FD-WD

The FD-WD and FD-WD-H sensors enable a robotic deviation detection system used for finding linear changes in a part. Wire sensing is the most common sensing method available. No additional hardware is required (all sensing is performed via the weld wire).

[btn text="Download more information" tcolor=#FFF bcolor=#004098 thovercolor=#FFF link="https://daihen.mx/wp-content/uploads/2020/04/Sensing-Solutions.pdf" target="_blank"]