Description

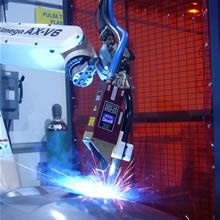

ADAPTIVE WELDING FUNCTION FOR HIGH PRECISION WELDING

For best welding results, the FD-QT sensor utilizes an optional adaptive welding function that modifies the welding conditions (welding current, voltage, speed) as needed – all in real time.

- Designed for harsh arc welding environments

- Compact design and easy maintenance

- Dedicated menu provides user-friendly interface and easy-to-use operation via the teach pendant

- Advanced 3D tracking technologies provide stable and accurate tracking results

- Full support for all equipment (Robot, Welder and Sensor) from OTC DAIHEN