Descripción

El sistema FD-TR es capaz de rastrear en tiempo real para compensar defectos en partes como distorsión, mal ajuste, accesorios flojos y más. Disponible para una amplia gama de espesores de placa, 0.040 ″ (1.0 mm) y mayores.

- Operación simple y fácil a través del menú dedicado en el Teach Pendant

- No hay problema en entornos de soldadura TIG

- Alta fiabilidad y versatilidad.

- Excelente para todos los espesores de placa.

- Las configuraciones y controles en el Teaching Pendant están en un menú dedicado fácil de usar

- Configuración simple que se puede conectar a cualquier tipo de máquina OTC DAIHEN TIG

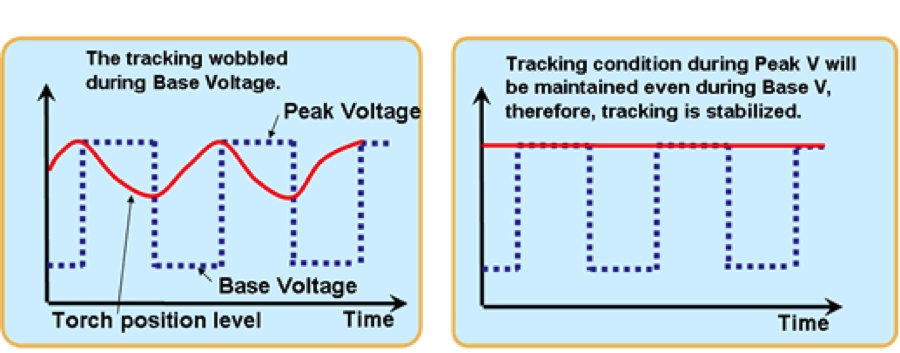

- Seguimiento estable y preciso