Description

The FD-TR system is capable of real time tracking to compensate for defects in parts such as distortion, poor fit-up, loose fixtures, and more. Available for a wide range of plate thicknesses, 0.040″ (1.0mm) and greater.

- Simple & Easy operation via dedicated menu in the Teach Pendant

- No problem in TIG welding environments

- High-reliability and versatility

- Excellent for all plate thicknesses

- Settings and controls in the Teaching Pendant are in a dedicated user-friendly menu

- Simple configuration that can be connected to any type of OTC DAIHEN TIG machine

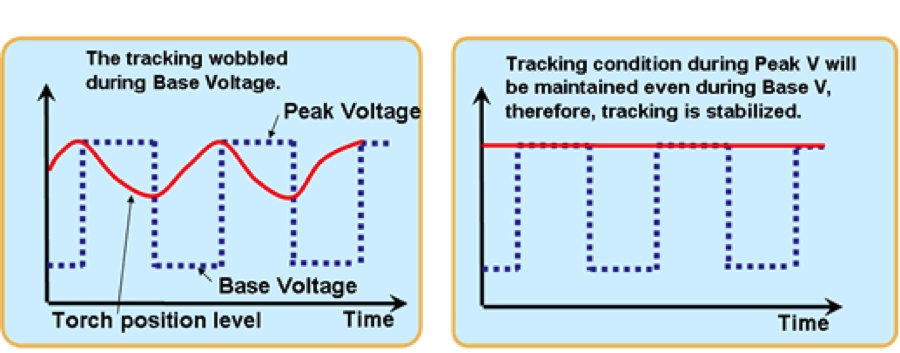

- Stable and accurate tracking