Description

QUICK AND ACCURATE PART DEVIATION DETECTION

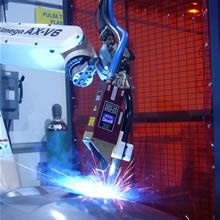

The FD-QD (Quick Detect) is a 3D laser search system that boosts your productivity by recognizing problems before they occur. This incredible system shifts its taught programs to match the actual location of the work pieces – even with difficult joints. FD-QD is well suited for a variety of applications, including standard MIG, TIG, and air plasma cutting.

FD-QD can switch the welding condition automatically, according to the detected gap. Response time is blazing fast – FD-QD can search at speeds of up to 200cm/min. FD-QD is ideal for thin plate applications that can not be monitored by touch sensor. All search parameters are set via the teach pendant. Laser detection provides quick sensing with the highest degree of accuracy.

DESIGNED FOR ARC WELDING APPLICATIONS.

- Full operation via teaching pendant

- Unique concept sensing system with better versatility for deviation detection

- Fully integrated functions developed by DAIHEN